|

|

|

Powder Details

|

VA5073

|

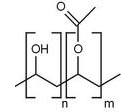

VA5073 - Polyvinyl Alcohol (PVA)

VA5073 is a medium viscosity, fully hydrolyzed grade of polyvinyl alcohol. White and granular powder, it is soluble in hot water but insoluble in cold water and common organic solvents. For most applications, VA5073 is prepared in water solutions. On evaporation of water, transparent films are formed which have high tensile strength and tear resistance. The binder characteristics of offer excellent adhesion to porous, hydrophilic surfaces.

Typical Properties

Viscosity, cps1 27.0-33.0, Viscosity in mPa.s (cP) of a 4% solids aqueous solution at 20°C (68°F)

Solution, pH 5.0-7.0, Mole percent hydrolysis of acetate groups, dry basis

Volatiles, wt. % max. 5.0

Ash, wt. % max.3 0.70, Dry basis, calculated as % Na2O

Suggested Uses

VA5073 offers a combination of excellent film forming and binder characteristics, along with insolubility in cold water and organic solvents. This combination of characteristics is useful in a variety of applications. VA5073 is widely used in the paper industry at the size press and calender stack, and in adhesives tackified with boric acid.

Adhesives

In adhesive applications VA5073 can be used alone or often in combination with extenders such as starch, dextrin or clay. As the proportion of increases, the adhesive strength and water resistance also improve. Examples of adhesives applications include:

· for paper and paperboard, alone or in combination with other additives;

· as a component in industrial adhesives for bonding paper, textiles, leather, films and porous substrates;

· for laminating adhesives which are used in the manufacture of solid fiberboard, linear board, spiral wound tubes and cores, and laminated specialties;

· in bag adhesives and pastes; and

· as an adhesive in corrugated container board.

The medium viscosity gives flexibility in formulating water based adhesives with boric acid with or without clay and/or starch.

Paper and Paperboard Sizing and Coatings

In sizing and coatings for paper and paperboard, VA5073 can be used alone or combined with starch and/or pigment. The proportion of to be used depends on desired physical properties and economics. Some specific paper uses include:

· For fine writing and printing papers as surface size material with starch;

· as grease-proof coating or release coating on paper specialties; and

· as binder in pigmented size press coatings to provide pigment loading.

· When substituted for all or part of the starch, the lower binder add-on improves opacity and makes the paper less yellow.

· VA5073 is easily jet-cooked alone or with starch with no additional holding time required after cooking.

· ElvanolÒ VA5073 has found wide use as a calender stack treatment for controlling curl and linting for paperboard grades.

· VA5073 is a good choice as a carrier for grease and oil-resistant treatments applied at the size press or calender stack.

Films

Unsupported films cast from water solutions of VA5073 and plasticizers are transparent, tough, tear-resistant and punctureresistant. provides a unique combination of properties. Films have hot water solubility, in addition to resistance to oils, grease and solvents, and have low oxygen and water vapor transmission rates. These properties make films of 71- 30 suitable for dissolvable unit packages and hospital laundry bags where hot water solubility and cold water resistance is needed.

FDA Status

VA5073 polyvinyl alcohol complies with U.S. Food and Drug Administration (FDA) Regulations under the following Sections of Title 21 CFR, and may be used in contact with food, subject to the limitations and requirements therein:

· 175.105 - - Adhesives.

· 175.300 - - Resinous and polymeric coatings(1)

· 175.320 - - Resinous and polymeric coatings for polyolefin films (2)

· 176.170(b) - - Components of paper and paperboard in contact with aqueous and fatty foods(3)

· 176.180 - - Components of paper and paperboard in contact with dry food(4)

· 177.1200 - - Cellophane

· 177.1670 - - Polyvinyl alcohol film(5)

· 177.2260 - - Filters, resin-bonded(6)

(1) Subject to the finished food-contact article meeting the extractive limitations under the intended conditions of use, as shown in paragraph (c). (2) For use only as a dispersing agent at levels not to exceed 6 percent of total coating weight in coatings for polyolefin films provided the finished polyolefin films contact food only of Types V, VIII and IX (identified in 21 CFR 176.170(c), Table 1), subject to the finished food-contact article meeting the extractive limitations under the intended conditions of use, as shown in paragraph (c). (3) Subject to the finished food-contact surface of the paper or paperboard meeting the extract ive limitations under the intended conditions of use, as shown in paragraph (c) of the Regulation. (4) As a component of the uncoated and coated food-contact surface of paper and paperboard in contact with dry food (Food Type VIII, identified in 21 CFR 176.170(c), Table 1). (5) In the preparation of polyvinyl alcohol film that may be used in contact with food of Types V, VIII and IX (identified in 21 CFR 176.170(c), Table 1), provided the food-contact film in contact with food Types V or IX is subject to the finished food-contact surface of the paper or paperboard meeting the extractive limitations under the intended conditions of use, as shown in paragraph (b) of the Regulation. The finished food-contact film shall not be used as a component of food cont ainers intended for use in contact with water. (6) Subject to the finished resin-bonded filter meeting the extractive limitations under the intended conditions of use, as shown in the Regulation. In accordance with good manufacturing practice, finished f ilters should be thoroughly cleansed prior to their first use in contact with food. (7) For use in textiles and textile fibers that may be used as articles or components of articles in contact with dry food (Food Type VIII, identified in 21 CFR 176.170(c), Table 1). VA5073 data sheet, pg. 3 of 3 Safety & Handling Read and understand the Materials Safety Data Sheet (MSDS) before using this product. is technical quality polyvinyl alcohol. It is not recommended for inclusion in any food or preparation that might be taken internally. Under certain conditions of use, dust may be formed from polyvinyl alcohol. We recommends that dust from be treated as a nuisance dust, which is regulated by the Occupational Safety and Health Administration (OSHA) under Title 29, Code of Federal Regulations, Section 1910.1000. Under this section, an employee’s exposure to nuisance dust shall be limited to 15 milligrams per cubic meter (mg/m3) of total dust and 5 mg/m3 of respirable dust on a time-weighted average in any 8-hour shift of a 40-hour week. The limit for polyvinyl alcohol exposure to nuisance dust is 10 mg/m3, and for respirable dust is 5 mg/m3. If excessive concentrations of dust are encountered, a mask or respirator and goggles should be worn. The mask or respirator should comply with Section 1910.134 of the OSHA regulations; the goggles should comply with Section 1910.133. For bulk storage and handling of (e.g. storage silos) refer to Bulk Storage and Handling Safety Guide. may be disposed of by incineration or landfill. However, any disposal method must be in compliance with all applicable local, state and federal regulations |

|

|

|