|

|

|

Powder Details

|

VA5071

|

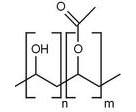

VA5071 - Polyvinyl Alcohol (PVA)

VA5071 is a unique, medium low viscosity, fully hydrolyzed copolymer grade of polyvinyl alcohol. Its unique structure imparts improved viscosity stability and gel resistance to aqueous solutions while maintaining excellent film properties and adhesive strength typical of fully hydrolyzed grades. Below are the typical properties of VA5071.

| Viscosity, csp1 | 11.6-15.4 | | Solution, pH | 5.0-7.0 | | Percent hydrolysis2 | Standard hydrolysis does not apply | | Volatiles, wt. % max. | 5.0 | | Ash, wt. % max.3 | 0.70 | | 1 Determinated at 20°C (68°F), by Hoeppier falling ball method, bone dry basis

2 V5071 is a copolymer of PVA and MMA and thus cannot be classified as a partially or fully hydrolyzed homopolymer. The hydrolysis reaction is taken to completion (less than residual 2% acetate groups), but the effect of the copolymer causes V5071 to act like a partially or intermediately hydrolyzed homopolymer.

3 Dry basis, calculated as % Na2O |

| Viscosity of 25°C (77°F), mPa.s (cP) 1 | | - | 1 day | 10 days | 3 wks | 4 wks | 6 wks | | V5071 | 758 | 764 | 774 | 780 | 800 | | Visible gel structure | None | None | None | None | None | | | Viscosity of 10°C (77°F), mPa.s (cP) 1 | | - | 1 day | 10 days | 3 wks | 4 wks | 6 wks | | V5071 | 1422 | 1668 | 1650 | 1650 | 1618 | | Visible gel structure | None | None | None | None | None | | 1 Brookfield, Model LVF, 60 rpm |

Characteristics

As illustrated below, solutions of VA5071 exhibit little tendency to increase in viscosity during storage. Solutions of VA5071 are much more resistant to temperature variation in that they develop essentially no gel structure if chilled lower than room temperature.

Suggested Uses

VA5071 is suggested for evaluation wherever the high film strength and oil, grease and solvent resistance associated with higher viscosity, fully hydrolyzed polyvinyl alcohol are desired, but a lower solution viscosity and gel resistance are needed. The viscosity stability of VA5071 solutions makes it attractive for use in wet adhesives that require long term storage stability and which must withstand temperature variations, either in storage or during shipment. Gel resistance and excellent binding properties of VA5071 suggest its use as a secondary, or even a principle binder, in the manufacture of joint cements.

Safety & Handling

VA5071is regarded as a safe, nontoxic material when properly handled. VA5071is technical quality polyvinyl alcohol. It is not recommended for inclusion in any food or preparation which might be taken internally.

Under certain conditions of use, dust may be formed from polyvinyl alcohol. We recommends that dust from VA5071be treated as a nuisance dust, which is regulated by the Occupational Safety and Health Administration (OSHA) under Title 29, Code of Federal Regulations, Section 1910.1000. Under this section, an employee’s exposure to nuisance dust shall be limited to 15 milligrams per cubic meter (mg/m3) of total dust and 5 mg/m3 of respirable dust on a time-weighted average in any 8-hour shift of a 40-hour week.

Suggested limit for polyvinyl alcohol exposure to nuisance dust is 10 mg/m3, and for respirable dust is 5 mg/m3. If excessive concentrations of dust are encountered, a mask or respirator and goggles should be worn. The mask or respirator should comply with Section 1910.134 of the OSHA regulations; the goggles should comply with Section 1910.133. For bulk storage and handling of VA5071(e.g. storage silos) refer to the VA5071Bulk Storage and Handling Safety Guide. VA5071may be disposed of by incineration or landfill. However, any disposal method must be in compliance with all applicable local, state and federal regulations.

FDA Status

VA5071 polyvinyl alcohol complies with U.S. Food and Drug Administration (FDA) Regulations under the following Sections of Title 21 CFR, and may be used in contact with food, subject to the limitations and requirements therein: · 175.105 - Adhesives |

|

|

|