|

|

|

Powder Details

|

IA1225

|

Calcinated Alumina Powder – IA1225

Designed for use in metal lapping when high cut-rate and low surface roughness is desired. Tightly sized through air classification. Used in polishing and buffing compounds, heat sink additives, thermal conductivity/electrical resistant coatings, and as an abrasion resistant coating (metals) or additive (plastics, epoxies, laminates).

| Physical Characteristics | Chemical Composition | | Crystal Form | Monocrystalline Alpha Alumina | Al2O3 | 98.70% min. | | Shape | Hexagonal Platelets | SiO2 | 0.06% max. | | Hardness | Knoop – 2000 | Fe2O3 | 0.03% max. | | pH | 9.0-10.5 | Na2O | 1.00% max. | | Specific Gravity | 3.95 gm/cc | TiO2 | 0.02% max. | | - | - | CaO | 0.07% max. | | - | - | MgO | 0.05% max. |

| Product | IA1203 | IA1225 | IA12E4 | | Grade | Industrial Grade | Industrial Grade | Electronic Grade | | Medium Particle Size | 3 um | 25 um | 0.4 um (95% less than 1.0 micron and no particles larger than 2.0 microns.) | | Typical Al2O3 content | 98.7% | 98.7% | 99.7% | | Typical Application | Used in polishing and buffing compounds, heat sink additives, thermal conductivity/electrical resistant coatings, and as an abrasion resistant coating (metals) or additive (plastics, epoxies, laminates) | Used in polishing and buffing compounds, heat sink additives, thermal conductivity/electrical resistant coatings, and as an abrasion resistant coating (metals) or additive (plastics, epoxies, laminates) | Used as a nonmagnetic additive in magnetic media coating formulations for high density floppy discs as well as high grade audio and video tape where high quality, tight sizing and 2.0 micron coarse particle control are required. |

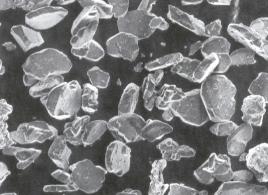

Calcined alumina grains are normally composed of single platey crystals, whereas fused aluminum oxide grains tend to be fractions of large crystals and blocky in shape. A calcined crystal is theoretically a six-sided disc with a thickness of about one fifth of its diameter. This will vary from one type of crude to another but remains fairly consistent for any given type of calcined alumina.

The measurement of the diameter of the particle is referred to as the material’s “ultimate crystal size.” The crude alumina is composed of aggregates of crystals which are broken up in a milling process to produce a material of individual crystals in the ultimate crystal size.

Calcined aluminas are more pure than fused aluminum oxide products with the exception of fused white aluminum oxide (both over 99% Al2O3). Calcined aluminas, when milled, retain the chemistry of the unmilled crude more closely than fused aluminum oxide. For example, dark fused aluminum oxide crude (typically 96% Al2O3) when processed into lapping powder sizes, will typically lose several percentage points of Al2O3. This is because the impurities in the crude are more easily crushed and migrate into the fine powder sizes.

|

|

|

|